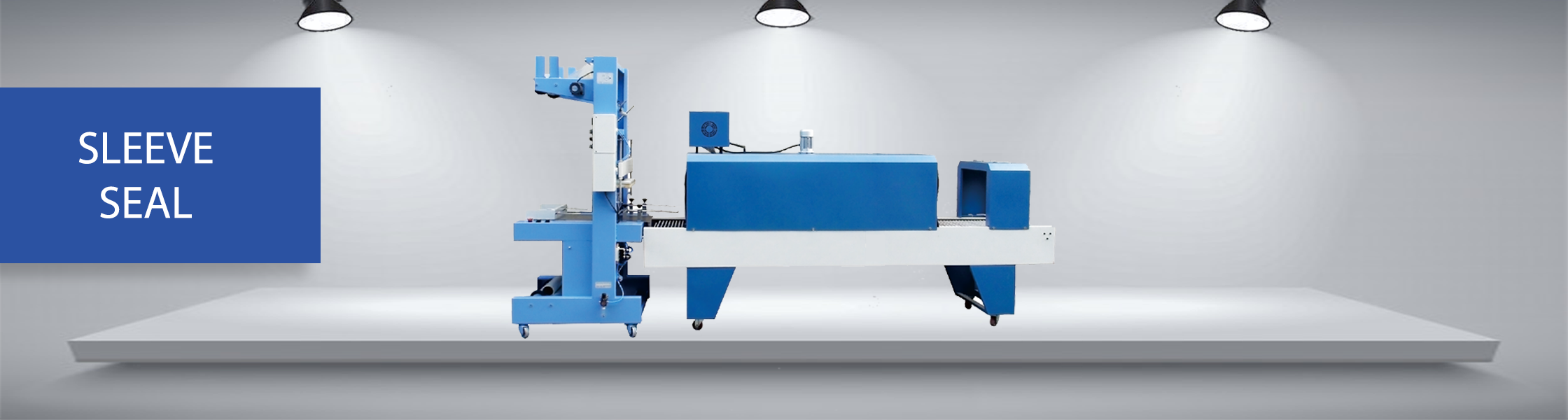

Sleeve Sealer & Shrink Tunnel

Packaging Video

Sleeve Sealer and Shrink Tunnel is a common way of packaging large products with many benefits. The machine can automatically feed, transport, seal and shrink efficiently. Shrinkable materials such as PE, PVC, BOPP, POF film are optional to choose depending on the standard and purpose of packaging. As a packing machine, the heat shrink wrapping machine can make a high standard package with great capacity. The wrapped products are waterproof and dustproof, clear or designed, and neat packaging material.

Our Packaging Machines USA Ranges

Our range of L-Bar Sealers, Sleeve Sealers, and Side Sealers, as well as Shrink Tunnels are ideally suited to a wide variety of applications and can be customised according to your production needs. All individual modules that comprise our Shrink Wrap range like infeed and discharge conveyors, multi-lane conveyors, dual infeed rails, and pack cooling racks are available in different versions according to your production requirements.

Sleeve Sealers are utilised for the shrink wrapping of daily necessities, health care products, stationery, tobacco packaging, bottles, workwear, towels, aerosol containers, moulded panels, cans, large household goods, timber, paint pots, magazines and newspapers, flat pack furniture and any round or long products.

- Product-sensing horizontal and verticals eyes, and time relay offers superior packing quality whilst preventing inconsistent film applications, in-transit product movement, tampering or damage

- Operators have precise control over angular and linear positions, as well as packaging velocity

- Wrapping speeds up to 28 collations per minute / 1 680 per hour subject to pack size

- Modular design with line integration, automatic temperature control, automatic alignment, adjustable feeding sensor, and precision lock-up sleeve for greater efficiency

- PTFE mesh belt Conveyor with 2-inch pitch

- Infeed and dispatch conveyor speeds are adjustable through a variable speed drive system

- Automatic cool down cycle helps to cool packaging

- Adjustable sealing plate ensures a clean sealing line and smooth cutting without cracking or film sticking, and sealing temperature is adjustable

- User-friendly, bilingual PLC touch screen interface and HMI control technology offers optimal coordination between the servo motor and photo-electric sensors to improve sleeving accuracy and efficiency, and boosts custom programs input and storage capacity

- Durable stainless-steel frame is fitted with a safety guard to protect operators against injury

- Precise coordination between modules allows for easy product changeovers

- Heavy-duty, height-adjustable sealing jaw produces consistently strong seals at high speeds

- Integrated programming allows the Sleeve Sealer to complete a combination of single to multi-row packaging according to production requirements without separate moulds

- Automatic pack counting allows for better production volume statistics

By integrating a Shrink Tunnel into your packaging line, time and labour expenses are severely reduced as production efficiency increases exponentially.

Automatic in-line Sleeve Sealers are the ideal shrink wrapping solution for high production volumes of a wide variety of goods, mainly for display, transportation, and distribution purposes.

Products are fed from an inverter-driven, heat-resistant mesh belt conveyor. Smart photo-electric sensors relay product instabilities to the onboard micro-controller that automatically maintains product alignment as goods move along the line to the sealing chamber.

The sealing station is fitted with top and bottom film roll holders that are designed to create a curtain of PE, PVC, BOPP, or POF shrink film at the mouth of the sealing chamber. Products pass through this curtain where a two-way vertical drive system enables the sealer to create a sleeve around them.

With the help of product pack clamps, sleeves can be formed in either long, single or multi-row, or collated tray formats, in effect leaving two small openings on opposing sides of the wrapped products.

Sleeve Sealers use product-sensing horizontal and verticals eyes, coupled with a time relay and a specialised, adjustable sealing blade that can be adjusted according to product size. This helps to ensure consistent, neat, and durable wrapping applications that will prevent in-transit movement, product tampering and damage for when goods are dispatched.

Additional guides, pad-feeding magazines, dye cut cardboard sheets, and stacking mechanisms can form part of the packaging process before the packaging enters a shrink tunnel for final shrink wrapping.

Packaging Application